Indiana Glass, celebrated for its exquisite Carnival and Depression glass creations, has enchanted collectors with their detailed designs and radiant allure. Since its inception in 1907, Indiana Glass has risen to prominence among enthusiasts of fine glassware. This article delves into the captivating history and enduring patterns that define these cherished collectibles while offering essential tips for recognizing and acquiring these prized items favored by collectors.

Key Takeaways

Indiana Glass Company, established in 1907 and stemming from the Beatty-Brady Glass Company, significantly contributed to Dunkirk’s economic development using regional resources and transitioning through energy sources like coal gas for glassmaking.

The company became famous for its diverse designs and patterns, including Depression Glass and Carnival Glass, evolving to craft new designs from old molds, and came to include unique items, such as the Hen-on-Nest dish, within its collector-friendly repertoire.

Despite its eventual closure and facing challenges such as increased competition from imported glass, Indiana Glass’s legacy persists, with its products still sought after by collectors and enthusiasts for their historic value and craftsmanship.

The Heritage of Indiana Glass Company

In 1907, a determined group headed by Frank W. Merry took over the Dunkirk glass plant after acquiring it from the insolvent National Glass Company, thus founding the Indiana Glass Company. This new company harnessed East Central Indiana’s ample natural gas reserves to fuel its operations and contribute substantially to Dunkirk’s economic growth.

With the depletion of these natural gas deposits by 1905, The Indiana Glass Company transitioned to utilizing coal gas derived from West Virginia and Kentucky for their glass production processes. The company managed through such hurdles successfully and earned acclaim for producing premium quality glass items. Its Depression-era and carnival glass pieces have particularly gained recognition among collectors who continue to treasure them up until now.

The Beatty-Brady Origins

Prior to the emergence of the Indiana Glass Company, its precursor, the Beatty-Brady Glass Company, had set the stage for what would become a thriving glass industry in Dunkirk. George Brady and James Beatty established this company back in 1896 with a focus on crafting.

various types of glass lamps

lamp chimneys

decorative vases

an assortment of domestic glassware

This enterprise rose to prominence as one of the key players among glass manufacturers. Their operations took root in a sizeable complex that was originally designated for servicing Pennsylvania Railroad freight cars but later repurposed to accommodate their burgeoning needs for producing high-quality glass items.

Nevertheless, navigating through tumultuous times proved challenging. Financial depressions at the close of the 19th century along with severe banking turmoil were compounded by aggressive measures against labor unions that spawned legal complications. Facing these headwinds led them down a path towards consolidation – culminating in their merger into National Glass Combine during 1899 – whereby they aligned themselves alongside eighteen other distinct companies within this formidable alliance dedicated to specializing in intricate glass production.

Transition to National Glass and Formation of Indiana Glass

At the dawn of the 20th century, there was a notable transformation within the glass industry. Facing financial difficulties, National Glass Company ceased operations in all their plants by the end of 1904. This cessation paved the way for Frank W. Merry to take over and lease one such plant situated in Dunkirk. Consequently, this move led to the establishment of Indiana Glass Company three years later.

In subsequent developments, after National Glass succumbed to receivership, Frank Merry together with his business partners acquired ownership of the Dunkirk facility, finalizing this transaction by 1909. Holding presidential responsibilities from when it was incorporated until 1931, Merry played a crucial role during those critical initial decades ensuring that Indiana Glass Company solidified its reputation as an iconic entity in glass manufacturing.

A Spectrum of Glass Patterns and Designs

Indiana Glass set itself apart from competitors through a diverse selection of glass patterns and styles. This company played an essential role in the creation of Depression Glass, which emerged as the inaugural machine-made mass-market glassware that was economically priced. Available from around 1920 until 1940, this refined yet affordable tableware became widely prevalent across American homes during that period’s economic hardship.

The array of designs produced by Indiana Glass included Carnival Glass, known for its gleaming iridescence reminiscent of crystal. Its palette featured hues like blue, gold, sunset orange, lime green and amethyst among others – each adding a touch of elegance to the collection.

In pursuit of modern innovation while honoring their history in the ‘70s Indiana revisited older molds to shape new patterns and forms within their Contemporary Carnival Glass series. Towards the late 1930s there had been a pivot away from earlier production methodologies associated with Depression-era pieces toward more sophisticated automated mold techniques for crafting their signature glass items.

Signature Series: From Avocado to Tea Room

Indiana Glass distinguished itself with an array of patterns that captured both classical beauty and innovative craftsmanship. The company debuted its Avocado pattern in 1923, which quickly became a staple among Depression-era glassware for integrating Art Nouveau flair into the latest advances in molded glass production. This approach seamlessly blended time-honored designs with cutting-edge technology.

Incorporating advancements in design, Indiana Glass rolled out new patterns such as the Lorain #615 pattern by 1929. This particular mold-etched creation interwove floral motifs with Art Deco influences. The Sandwich pattern also emerged from this era’s creative drive, drawing on molds developed in the 1920s before later being associated primarily with Tiara Exclusives—a move demonstrating Indiana Glass’s knack for fusing historic aesthetics within modern-day manufacturing processes.

The revival of historical success was evident when Indiana Glass re-launched their Heirloom series during the carnival glass resurgence of the ‘70s under their Contemporary Carnival collection label. Continuing to enhance its product range across various styles, they introduced numerous coveted collector items designed not only for practical use but also as intriguing decorative accents under distinctive marketing labels like ‘Goldentone’ and ‘Florist Selection’.

The Novelty of Goofus and Carnival Glass

Another novel line that Indiana Glass was known for was the Goofus Glass. This economical cold-painted glass, though not permanent and prone to flaking, was one of the early products of Indiana Glass and added to the company’s diverse product range. Additionally, the company became renowned for its Carnival Glass lines, such as the Harvest and Heirloom patterns, which have become highly recognizable and collectible.

The popularity of the Carnival Glass line was further cemented by the introduction of distinctive designs like the Hen-on-Nest and Egg Hors D’oeuvre Dish. The company also expanded its Carnival Glass offerings to include handled baskets and bonbon dishes with intricate patterns like Lily Pons, Loganberry, and Sweet Pear, further enhancing their product diversity and appeal to collectors.

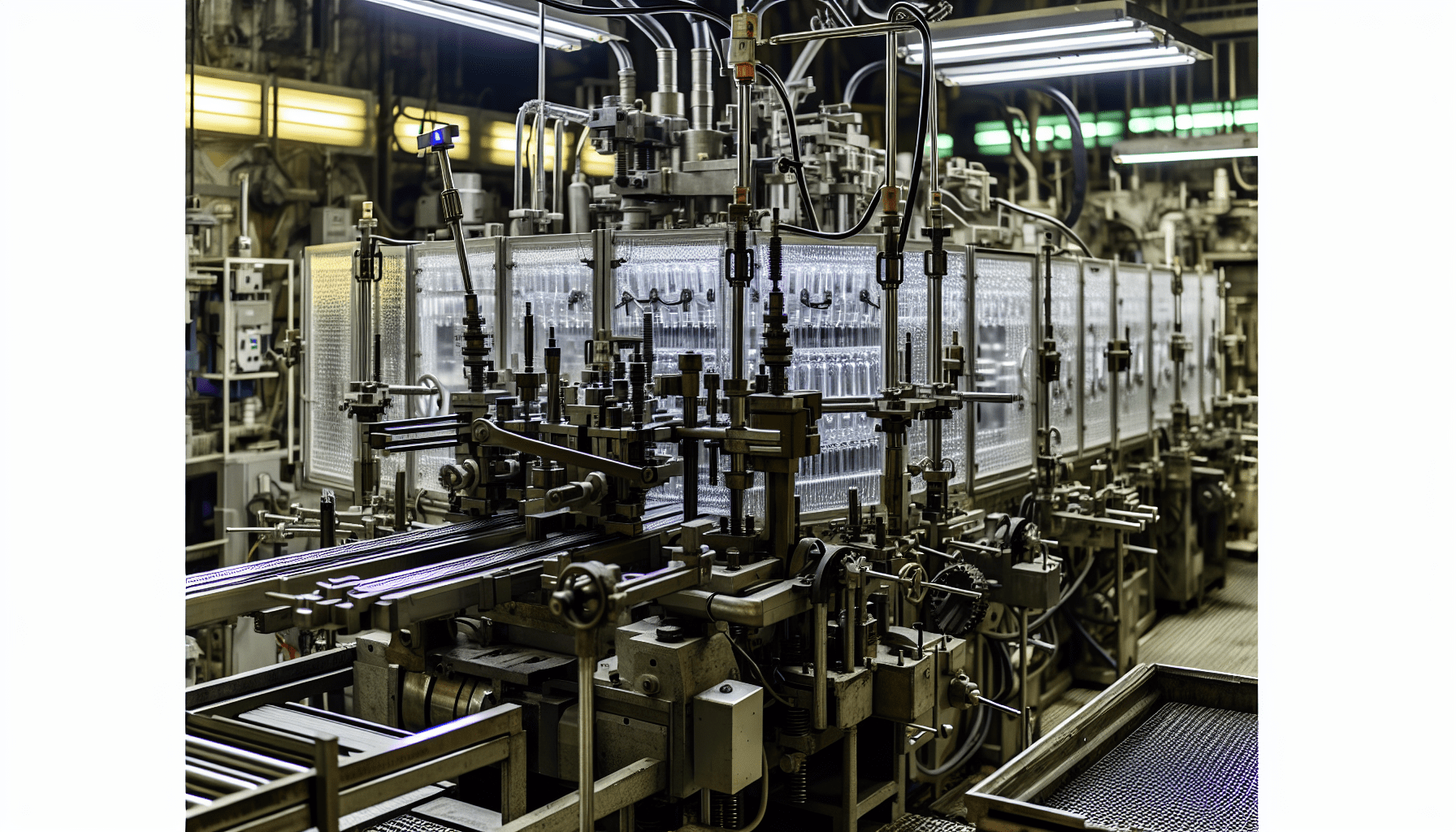

The Manufacturing Marvel

Indiana Glass distinguished itself not only with a variety of designs but also through groundbreaking production techniques. Benjamin F. Gift revolutionized the industry in 1916 by obtaining a patent for a novel machine that enhanced the cooling process of shaped molten glass, representing an important leap forward in technology. Subsequently, Jeddiah B. Clark, another Indiana Glass associate, secured a patent in 1931 for improving procedures involved with molten glass management which bolstered the performance of equipment used in blowing or pressing glass.

Accompanying these technical advancements was the deployment of an automatic tumbler machine introduced by Indiana Glass during that same pivotal year of 1916. This move signified a significant trend towards automation within the realm of glassware production. Such strides propelled Indiana Glass to become one of Dunkirk’s major employers—boasting over 1,000 workers at its zenith—as it played an essential role within that community’s economic fabric. The company extended its impact economically beyond local confines when it opened up operations in Sapulpa, Oklahoma. By cementing employment figures upwards around more than 1,300 employees by 1979, the firm underscored its critical contribution to fostering job opportunities.

Innovations in Molded Glassware Production

Indiana Glass demonstrated a clear commitment to innovation, particularly through the advancement of technology in molded glassware manufacturing. In 1916, Benjamin F. Gift introduced his patented machine that revolutionized the industry by automatically moving molds away from hot molten glass. This automation allowed for improved cooling and facilitated easier removal of finished glassware products, marking an important development in enhancing both efficiency and quality within the production process.

In another groundbreaking move in 1931, Jeddiah B. Clark’s invention streamlined the process even with his patented technique that increased effectiveness when transferring molten glass into shaping machines. Together with the introduction of an automatic machine designed specifically for tumblers, these advancements significantly accelerated production rates while ensuring consistent dimensions across tumbler products—thereby expanding Indiana Glass’s manufacturing capabilities while sustaining its reputation for high-quality output through employing similar innovative technologies.

The Lancaster Era: Expansion and Diversification

During the 1970s, Indiana Glass experienced notable growth and broadened its product range. The company’s line of Carnival Glass was particularly successful, finding a place in major retail chains such as K-Mart. Yet, the firm encountered economic difficulties that posed challenges to its operations.

Barington Capital Group L.P., in 2006, pushed for Lancaster Colony to sell off its glass division. This led to the end of an era with Lancaster Glass Corporation being sold by Lancaster Colony to Monomoy Capital Partners LP in November 2007. Consequently, Indiana Glass underwent a significant transformation when it became part of Anchor Hocking Company—a well-established entity within the realm of glassware production.

Tiara Exclusives: A New Marketing Frontier

In the period of the Lancaster era, Indiana Glass initiated Tiara Exclusives—a direct sales initiative utilizing a home party strategy to enhance their brand’s visibility and drive product sales. The premiere collection released for this venture was the Sandwich pattern, introduced in Ruby color within the 1970 Tiara Exclusives catalog and subsequently available in various hues to match prevailing interior design trends.

To manufacture its distinctive range of products under Tiara Exclusives, collaborations were formed with several glass factories such as Fenton Art Glass and L.E. Smith Glass. Following the shutdown of Indiana Glass in November 2002, production activities for Tiara Exclusives merchandise moved forward at Bartlett Collins Factory, which allowed for sustained availability of these cherished items.

The Golden Years and Federal Glass Merger Attempt

In 1977, the glass company known as Indiana Glass ascended to a prominent position within its industry, becoming the fifth-largest producer of glassware in the United States. During this time, it reported sales reaching approximately $36 million from its machine-manufactured glass products. Two years later, in 1979, employment at their Dunkirk facility peaked with around 1,300 workers—marking an era of considerable success for the company.

During that zenith year of prosperity, Indiana Glass attempted an alliance through merging with Federal Glass Company. These plans were thwarted by resistance from the FTC who had concerns about reduced competition and potential monopoly risks if such a merger went ahead.

Challenges and Closure: The Decline of an Industry Giant

Indiana Glass, renowned for its storied past and numerous accomplishments, encountered formidable obstacles toward the end of the 20th century. The company was beset by financial struggles and intensified competition from more affordably priced foreign imports. This adversity resulted in a reduction of operations and closures at various facilities, signifying a downturn for this prominent entity within the industry.

During the mid-1980s, competitive forces precipitated the shuttering of one Dunkirk facility, which caused approximately 200 employees to lose their jobs. Then in November 2002, persistent economic hardships coupled with continued declines in business prompted another shutdown at Dunkirk plant that culminated in an additional 240 job losses.

The Impact of Global Competition

Global competition has significantly affected Indiana Glass, particularly due to the Caribbean Basin Initiative and the Israel–United States Free Trade Agreement. These trade policies enabled a surge of inexpensive imported glassware that adversely influenced the financial health of domestic manufacturers, including firms such as Indiana Glass.

Holding its place as the third-largest producer of glassware domestically, Indiana Glass experienced considerable challenges to both its fiscal stability and standing in the market owing to this heightened competitive pressure from low-cost imports. Even with its prominent status within the industry, Indiana Glass’s position suffered due to these cheap importations inundating their market segment.

The End of Glassmaking in Dunkirk

In 2002, Indiana Glass experienced the closure of its Dunkirk factory, a pivotal establishment in operation since 1895. This cessation signified the close of more than a century’s worth of glass production at that location and led to approximately 240 individuals losing their jobs. Despite this significant reduction, between 50 and 60 positions were preserved for activities related to shipping, warehousing, and operating within the mold shop.

The factors precipitating this shutdown were multifaceted.

A downturn in profit margins

The insolvency proceedings faced by Kmart Corporation—one of its primary clients

An increasingly difficult commercial market

Disruptions from labor strikes lasting three months

The impacts brought on by an economic downturn

Nevertheless, despite ceasing operations in Dunkirk, Indiana Glass Co. had intentions to continue producing glassware under its established brand name at another plant situated in Sapulpa, Oklahoma.

Indiana Glass Today: Collecting and Legacy

Presently, the creations of Indiana Glass are coveted by collectors who appreciate their distinctive designs and rich history. Especially prized are pieces from select series, such as Harvest and Heirloom patterns. The scarcity of particular hues within these collections, for instance blue Carnival Glass, increases both their worth and appeal.

Maintaining the original stickers and tags on Indiana Glass items can considerably boost their value to collectors. There is a consistent market demand for these goods, which frequently find new homes through antique shops, flea markets, and internet auctions. It’s the exceptional craftsmanship behind Indiana Glass products that ensures they remain sought after by those who value quality across generations.

Where to Find Indiana Glass Pieces

Collectors in search of Indiana Glass pieces have a wealth of options to consider. Available venues for acquiring these glassware items include:

Virtual marketplaces like eBay and Etsy, along with specialized antique glassware websites

Antique stores, especially within the Midwest where the firm originated

Various flea markets throughout the country

Estate sales often present opportunities to discover Indiana Glass products, potentially as part of more extensive sets or amassed collections from dedicated aficionados. Collector events and gatherings serve dual purposes for enthusiasts. They provide an exciting environment not only to purchase cherished Indiana Glass articles but also to connect with fellow collectors and knowledgeable professionals in the field.

Preserving the Craft: Clubs and Collector Groups

Enthusiasts of Indiana Glass maintain their passion and preserve their heritage through the active involvement in collector groups, gatherings, and online forums. The recent occurrence of the Indiana Glass Collectors Convention in Portland, Indiana is a prime example where devotees congregate to celebrate their shared interest. These assemblies cultivate camaraderie and an earnest enthusiasm for collectors who may also find a collector’s encyclopedia an indispensable tool.

Online platforms equally contribute to uniting collectors from disparate regions. For instance, the Facebook group dedicated to the Indiana Glass Collectors Convention serves as a virtual meeting point where aficionados can engage with one another. It’s on these digital venues that they exchange discoveries, discuss various patterns unique to this glassware legacy, and sustain vibrant engagement within the collecting community of Indiana Glass.

Summary

Starting off as the modest Beatty-Brady Glass Company and evolving into the celebrated Indiana Glass Company, this emblematic firm stands as a tribute to human creativity and perseverance. Confronting numerous obstacles and transformations, it has managed to make an indelible mark on the glass industry. The distinctive designs and superior quality of its products still enchant collectors today. Honoring Indiana Glass brings forth an appreciation for the eternal beauty of expertly created glassware along with recognition for the talented craftsmen responsible for these treasures.

Frequently Asked Questions

Is Indiana Glass still in business?

Indiana Glass halted its glass production activities in Dunkirk back in 2002.

Is colony the same as Indiana Glass?

Indeed, Colony is synonymous with Indiana Glass, and their products are sold under the Color Crown series.

The pieces accented with Gold and Platinum are alternatively marketed as Colony items, specifically designated as Gold Crown and Platinum Crown.

Did Indiana Glass make crystal?

Indeed, Indiana Glass was renowned for producing crystal items such as pressed glass stemware, tableware, and lamps starting from 1900 up until the 1950s. These pieces have now become highly sought after by collectors.

Does Indiana Glass contain uranium?

Indiana Glass indeed possesses uranium, which is responsible for its glowing appearance when exposed to a black light. The quantity of uranium present in the glass is comparatively minimal.

When was the Indiana Glass Company established?

Founded in 1907, the Indiana Glass Company has been in operation for more than a century.